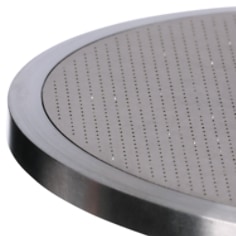

3M™ Trizact™ Pad Conditioner T Series

- 3M ID B5005469002

3M™ Trizact™ Pad Conditioner T Series

The epitome of our commitment to consistent, long-lifespan, metal-free cutting surface CMP pad conditioners. Launched in 2023, 3M™ Trizact™ Pad Conditioner T Series optimizes the surface topography for stronger pad activation, much slower wear and consistent performance throughout its lifetime.

Details

Highlights

- Enabled by proprietary 3M microreplication technology

- Extended lifetime and more stable removal rate compared to legacy designs

- Higher CMP pad wear rate to enable a more durable, lower-lifetime-cost solution

- Larger grain size for CVD diamond to enable stronger pad activation

- Improved with new microcrystalline CVD diamond coating technology

3M™ Trizact™ Pad Conditioner T Series delivers precision, consistency and reliability to semiconductor chemical mechanical polishing (CMP) processes. Advanced 3M CVD diamond coating technology offers highly consistent, strong, tunable pad activation for demanding semiconductor CMP specifications and processes, including advanced nodes. Each CMP pad conditioner provides microreplication technology to precisely shape the surface topography for excellent performance, without the risk of micro and macro scratching defects posed by conventional diamond grit abrasives.

-

Consistent Lifetime Performance

Consistent Lifetime Performance -

Metal-Free Surface

Metal-Free Surface -

Slower Pad Wear Rate Decay

Slower Pad Wear Rate Decay -

Yield Improvement

Yield Improvement

-

Conventional CMP pad conditioner

Conventional CMP pad conditionerAs pad conditioners wear down, the coefficient of friction decreases rapidly, leading to pad wear rate decay.

-

3M™ Trizact™ Pad Conditioner T Series

3M™ Trizact™ Pad Conditioner T Series3M™ Trizact™ Pad Conditioner T Series maintains the tunable surface topography of 3M™ Trizact™ Pad Conditioners and combines it with increased diamond grain size to strengthen pad activation and reduce pad wear rate. This rougher diamond coating has a higher coefficient of friction that helps reduce pad wear rate by up to 4X.

3M™ Trizact™ Pad Conditioner T Series

3M™ Trizact™ Pad Conditioner T Series 3M™ Diamond Pad Conditioner

3M™ Diamond Pad Conditioner 3M™ Trizact™ Pad Conditioner

3M™ Trizact™ Pad Conditioner 3M™ Diamond Pad Conditioner C Series

3M™ Diamond Pad Conditioner C Series