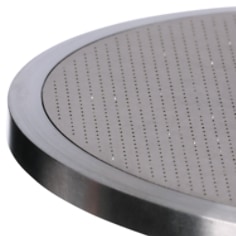

3M™ Diamond Pad Conditioner C Series

- 3M ID B5005469001

Details

Highlights

- Optimised diamond shape, pitch control and diamond orientation CMP pad conditioner

- Improved consistency and reduced disk-to-disk variation

- Slower pad wear rate decay with stable removal rate and profile

- Enables potential for longer disk life and pad life

- Uses 3M sintered abrasive technology for firm diamond adhesion

- 40% improvement in flatness control over legacy designs

3M™ Diamond Pad Conditioner C Series is a highly engineered chemical mechanical planarisation (CMP) pad conditioner that helps you deliver reliable performance in your critical semiconductor CMP applications. Refresh your CMP pad surfaces with 3M™ Diamond Pad Conditioner C Series. It also minimises wear and maintains consistent asperities and consistent pad performance — for wafer after wafer. These diamond disk CMP pad conditioners use 3M proprietary sintered abrasive technology for excellent diamond retention, helping enable longer life and better shape and diamond orientation control than legacy diamond CMP pad conditioners. The improved consistency and smaller variation enable you to reduce variables and optimise your CMP performance.

-

Improved Consistency

Improved Consistency -

Optimized Topography

Optimized Topography -

Tunable Performance

Tunable Performance

Broad range of conditioning performance options

Extra-precise diamond placement

-

Legacy 3M pad conditioner

Legacy 3M pad conditioner -

3M™ Diamond Pad Conditioner C Series

3M™ Diamond Pad Conditioner C Series

Specifications

Resources

Frequently asked questions

3M uses a proprietary sintered abrasive process that attaches diamonds to the substrate with both chemical and mechanical bonds to enhance diamond retention.

Selecting a CMP pad conditioner requires compatibility testing to ensure that your pad, wafer and slurry combination will perform optimally. Our technical team has data packages for many common chemistries — tungsten to copper, poly to STI, and many more — that have been proven compatible with our products. We can also test custom combinations at our labs around the world.

3M™ Diamond Pad Conditioner C Series elevates our more than 25 years of experience with diamond pad conditioners to a new level of precision. Diamonds are placed in a precise grid at the micrometer scale, and oriented to maximize flatness, co-planarity and conditioning performance.

3M™ Diamond Pad Conditioner C Series

3M™ Diamond Pad Conditioner C Series 3M™ Diamond Pad Conditioner

3M™ Diamond Pad Conditioner 3M™ Trizact™ Pad Conditioner T Series

3M™ Trizact™ Pad Conditioner T Series