3M™ Molded Assembly, 1M Series

- | Select product options for IDs.

Details

Highlights

- Excellent for robust long-term connections in high-vibration environments

- Excellent for use with or without high flex cables

- Molded one-piece design shields against elements

- Completed assemblies simplify parts management, virtually eliminates assembly costs

- Molded-in strain relief creates low height profile for space savings

- Compatible with standard .100” x .100” headers and board patterns

- PCB connectors are available in multiple pin counts and orientations for versatility

- Available also with PCB and DIP connectors

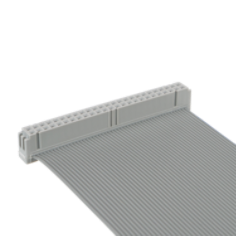

3M™ Molded Assembly 1M Series is excellent for applications requiring durable, long-lasting connections even in high-vibration environments and other difficult conditions. These fully customized connector/cable assemblies feature a rugged one-piece design and extra-strong beryllium copper contacts for extraordinary durability. Integrated strain reliefs and closed connector ends create a low height profile, maximizing use of board space and allowing for close stacking between components and boards.

-

Design Flexibility

Design Flexibility -

Durability

Durability -

Process Simplification

Process Simplification -

Vibration Tolerance

Vibration Tolerance

-

-

Features and benefits of 3M™ Molded Assembly 1M Series

Molded cable/connector assemblies feature durable flat cables for long-term performance in some of the toughest environments. Cable is concealed inside the connector body, greatly reducing the possibility of dirt and moisture entering through the connector while virtually eliminating the need for cable house assembly and parts management. The insulation material on the 3M assembly 1M series completely encases the gas-tight insulation displacement area and is thermally fused to the connector body, providing exceptional strain relief against pulls and other exterior forces. Cables can be specified with molded-in strain relief at points along the cable as well.

A. Gas-tight IDC area is encased in insulation

B. Cable and connector are thermally fused for exceptional strain relief

C. Individual contacts are isolated with thermoplastic cell walls

D. Recesses accommodate adjacent posts in continuous rows

The right cable/connector assembly for your application

3M™ Molded Assembly 1M Series connectors can be fully customized to meet exact specifications. One-piece molded assemblies can be specified with a range of 3M cables as well as DIP and PCB connectors. Sockets mate with industry standard .100” x .100” headers and plugs, with an optional ear latching mechanism for mating to latch/eject headers. A center bump is available on sockets for polarized connections. Cable assemblies use round conductor flat ribbon cable on industry standard .050” (1.27 mm) or 1 mm pitch.

3M™ Molded Assembly, 1M Series

3M™ Molded Assembly, 1M Series